Can Art

COMMITMENT to SUSTAINABILITY

At Can Art, we focus on using resources responsibly and protecting the environments where we operate. We’re committed to making our operations among the most energy efficient, safest and resilient in the industry.

We also believe in our people and communities. We’re proud to employ hundreds of men and women, and to foster the manufacturing and technical skills required for twenty-first century innovation.

We know our customers share these objectives. That’s why we collaborate across the entire value chain — from our primary suppliers and vendors to our customers and key partners — to reduce our environmental impacts, safeguard employee wellbeing and maximize product quality.

This document describes our approach to sustainability in further detail. We’ve taken numerous steps to embed an environmentally responsible culture throughout our manufacturing processes.

Herein, you’ll find an overview of the environmental, social and governance practices we use to identify and mitigate potential risks, as well as to capitalize on the enormous contributions our team makes to the sustainability and innovation of the broader economy — specifically the automotive, architectural, distribution and consumer products sectors, to name only a few.

OUR CONTRIBUTIONS TO A

SUSTAINABLE,

INNOVATIVE ECONOMY

Can Art Aluminum’s products serve diverse end markets, providing custom and standard aluminum extrusions for construction, automotive, furniture, signage and alternative energy applications, among others.

As an elemental material, aluminum's fundamental properties don’t change with mechanical processing, which means it can be recycled over and over again with no degradation. In this way, it’s infinitely recyclable.

Aluminum extrusions contribute to the energy efficiency of vehicles and buildings, with many positive sustainability outcomes.

For example, aluminum is an important component for light-weighting both traditional and electric vehicles. Lighter traditional vehicles use less fuel and therefore produce fewer carbon emissions. Lighter electric vehicles have longer ranges between charges.

Aluminum building materials provide a 100% recyclable alternative to materials like fiberglass and vinyl. They can also be produced to fit complex shapes, which reduces the need to fabricate other materials into less applicable sizes.

Can Art

PRIMARY END MARKETS

Electric Vehicles

Electric Vehicles

Traditional Vehicles

Traditional Vehicles

Building and Construction

Building and Construction

Distribution

Distribution

Construction Durables

Construction Durables

Can Art has won content on approximately 50% of all major North American electric vehicle programs launched to date

Can Art's meteoric rise in the vehicle electrification arena is driven by our relentless pursuit of excellence and innovation. We are spearheading ground-breaking developments in this transformative industry.

Environmental Practices

Built in 1995, our 110,000 square foot corporate head office and plant are located in Brampton, ON. In 2000, we added a 190,000 square foot manufacturing facility in Windsor, ON. This enhanced our ability to better service the North American market with proximity to Detroit. In pursuit of vertical integration we added a state-of-the-art 45,000 square foot anodizing facility in 2012 in Mississauga, ON. In 2016, Can Art created Astrex, a joint venture with Constellium in Lakeshore (Windsor), ON, adding 80,000 square feet of capacity to meet the growing demand for strong, light-weight, cost-effective aluminum extrusions used in automotive Crash Management Systems and body structure. In 2018, Can Art built a second building at our Windsor facility, increasing the site’s capacity by an additional 120,000 square feet. In 2024, Can Art will introduce its newest facility in Windsor to house 2 additional presses, the first of which will be installed in 2024.

We’ve taken numerous steps to embed an environmentally responsible culture throughout our manufacturing processes:

35% recycled aluminum as a percentage of metal input

20,000 MT (44M lbs) per year aluminum scrap recycled

Each ton of aluminum recycled (rather than produced from ore)

Can Art

USE OF SUSTAINABLE BILLETS

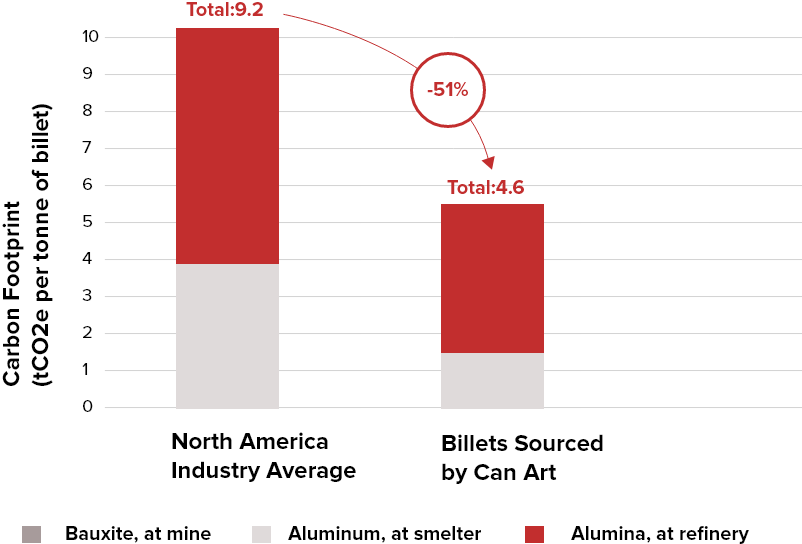

A key feature of our approach is our long-standing strategic partnerships to source sustainable aluminum extrusion billets.

Can Art partners with global leaders in metals and mining, which produce the lowest carbon footprint primary aluminum available among regional producers, as well as a range of sustainable aluminum products.

The aluminum extrusion billets produced at our partners’ facilities can contribute to obtaining internationally recognized green building certifications, such as Leadership in Energy and Environmental Design (LEED).

In order to achieve the LEED v4 rating, a building must contain materials that

-

Have an Environmental Product Declaration (EPD) lower than the average industry environmental impacts, including carbon footprint;

Have an Environmental Product Declaration (EPD) lower than the average industry environmental impacts, including carbon footprint; -

Are sourced from a sustainability-conscious supplier of raw materials; and

Are sourced from a sustainability-conscious supplier of raw materials; and -

Contain no hazardous materials in its provided list of ingredients.

Contain no hazardous materials in its provided list of ingredients.

Our use of low-carbon aluminum billets as a raw material in our products contributes to Can Art’s clients obtaining up to six points in the LEED v4 requirements.

Cradle-to-Gate Lifecycle Carbon Footprint of One Tonne of Primary Aluminum Billet

SOCIAL

PRACTICES

Can Art respects Canadian and international human rights standards and fosters a workplace of diversity and inclusion in employee-related processes, including hiring, remuneration, recognition, training and promotion.

Whistleblower mechanism

Our goal is to ensure that employees observe the highest standards of ethics in the conduct of their duties and responsibilities, practice honesty and integrity in fulfilling their responsibilities, and comply with all applicable laws and regulations

All employees are bound to the company’s Code of Conduct and Ethics, and are urged to report violations or suspected violations of the Code, and/or other possible legal and ethical lapses. If you suspect a violation,

GOVERNANCE PRACTICES

Can Art Aluminum is a privately owned North American business, specializing in standard and custom aluminum profiles. We are renowned for our dedication to quality, prompt service and proactive expansion in North America. Our governance approach includes:

Can Art

SUSTAINABILITY

PERFORMANCE

Can Art measures its sustainability performance on an annual basis. The table below presents a snapshot of our carbon footprint, energy usage and health & safety outcomes.

| Metrics | 2022 | 2023 | 2024 |

|---|---|---|---|

| Greenhouse Gas (“GHG”) Emissions (tCO2e) | |||

| Scope 1 | 8,312 | 8,364 | 7,256 |

| Scope 2 | 1,047 | 962 | 1,314 |

| Scopes 1 + 2 | 9,359 | 9,326 | 8,570 |

| Energy Usage (Gigajoules) | |||

| Natural gas usage | 153,697 | 141,111 | 121,478 |

| Other direct fuel usage | 4,845 | 15,698 | 15,083 |