Can Art

Can Art Recognized as a Market Leader for Providing Complex Parts

Overview

- 5,000 active dies (150+ automotive)

- 93 new dies launched in past 2 years (~25M kgs)

- 57% of new dies for EV programs

- 11 dies are very complex (~10M kgs)

- IATF, APQP (program management)

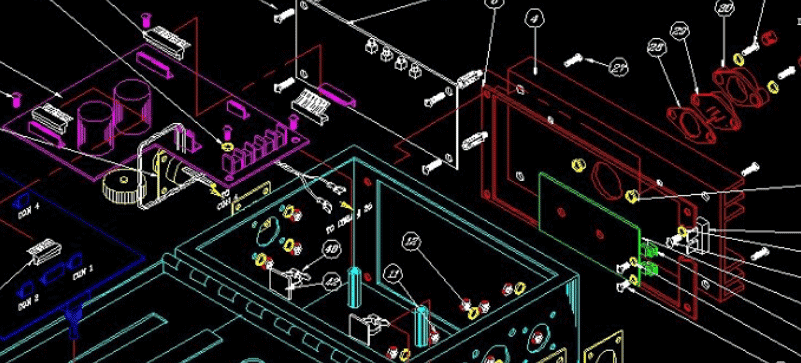

Die / Process Development

- 5 to 10 quote revisions from initial to award

- 1 to 1.5 years from award to SOP

- Average of 3 die iterations to achieve dimensions

- Average 10 to 20 die iterations to meet performance targets

- Established DOE process, average 12 months to reach target performance

- In-house die design/development and quench

Can Art

Tech Partners

- Alloy development (Rio Tinto & Matalco)

- Die makers (Thumb Tool & Exco)

- Extrusion equipment (SMS, Omav, Granco)

- Engaged with the University of Michigan (die flow, quench distortion study)

- Technical discussion directly with OEMS (e.g Ford, Rivian, Volvo)

Can Art

Can Art is proud to say that we are

IATF 16949 and ISO 9001:2015

certified