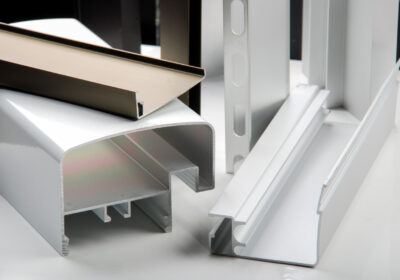

Electric vehicles aren’t just changing how we drive, they’re changing how we build cars. Every EV on the road today represents a remarkable blend of design, sustainability, and performance. And at the heart of it all? Aluminum extrusions.

These quiet workhorses of automotive engineering shape the EV industry in more ways than most people realize, from the battery enclosures that protect the vehicle’s core to the crash management systems that keep passengers safe.

At Can Art Aluminum Extrusion, we’ve seen firsthand how the right extrusion design can transform an EV platform, making it lighter, safer, and more efficient. Let’s unpack how aluminum is redefining the next generation of electric mobility.

- Lightweighting: Where Every Gram Counts

Ask any EV engineer what their biggest challenge is, and you’ll likely hear one word, weight. The heavier the car, the shorter the range. That’s why lightweighting has become the golden rule in EV design.

Aluminum gives designers the freedom to create strong, lightweight structures that outperform traditional steel parts in both efficiency and sustainability.

Why Aluminum Makes Sense for EVs

- It’s about one-third the weight of steel, but incredibly strong.

- 6000 series automotive alloys strike the perfect balance between strength, formability, and surface finish.

- It’s infinitely recyclable, making it a natural choice for a cleaner, greener mobility future.

From body-in-white frameworks to battery trays, aluminum extrusions help manufacturers shed weight without sacrificing stiffness or crash safety.

Why is aluminum used in electric vehicles?

Because it’s light, strong, and recyclable, improving range, performance, and sustainability all at once.

- Battery Enclosures: Protecting the Heart of the EV

If the battery is the heart of an EV, the enclosure is its armor. It needs to be lightweight yet strong enough to protect the cells, manage heat, and absorb impact. That’s where aluminum really shines.

What Makes Aluminum Battery Enclosures So Effective

- Excellent thermal conductivity for smooth heat dissipation and temperature control.

- Built-in crash resistance, thanks to extruded multi-hollow designs that absorb energy during impact.

- Corrosion resistance for long-lasting performance in harsh environments.

- Design flexibility, engineers can add grooves, channels, and mounting features right into the extrusion.

💬 Question Answered:

What are the benefits of an aluminum battery enclosure?

It keeps the battery cool, safe, and secure, while keeping weight down and performance up.

- Body-in-White & Space Frame Design: Strong, Light, and Modular

When it comes to vehicle architecture, aluminum extrusions are rewriting the rules. Instead of welded steel shells, modern EVs often rely on aluminum body-in-white (BIW) or space frame structures, lightweight yet incredibly stiff skeletons that form the vehicle’s backbone.

Why Engineers Love Aluminum Space Frames

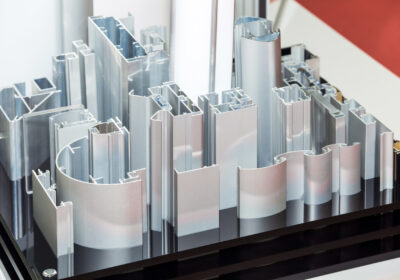

- Multi-hollow extrusions create complex, load-bearing shapes without excess weight.

- Integrated joints and connectors simplify assembly.

- Modular frame systems make it easier to design different vehicle types on the same platform.

- Outstanding energy absorption during collisions for improved passenger safety.

How does lightweighting improve EV range?

Less weight means less energy needed to move the vehicle, and that translates directly into more kilometers per charge.

Crash Management Systems: Built-In Safety by Design

Safety isn’t something you add at the end, it’s built right into the design. Components like bumpers, crash boxes, and crush cans made from aluminum extrusions are engineered to deform in a controlled way, absorbing the force of impact before it reaches the passenger cabin.

How Aluminum Makes EVs Safer

- Its unique structure allows predictable deformation, improving crashworthiness.

- Tight extrusion tolerances ensure consistent performance under extreme stress.

- It offers an excellent stiffness-to-weight ratio, making it ideal for safety-critical areas.

- And when damaged, it can be fully recycled, closing the loop on sustainable design.

What car parts are made from aluminum extrusions?

From crash beams and bumpers to battery trays, seat structures, and door reinforcements, aluminum extrusions are practically everywhere in a modern EV.

- Thermal Management: Keeping Cool for Maximum Range

Keeping an EV cool, especially its battery pack and power electronics, is crucial to performance and safety. Here again, aluminum extrusions are the unsung heroes.

Where Aluminum Helps

- Heat sinks and cooling plates maintain stable temperatures during charging and driving.

- Extruded channels integrate cooling lines seamlessly into the structure.

- High thermal conductivity ensures even heat distribution and battery protection.

Good thermal design extends battery life, enhances safety, and ultimately boosts vehicle range, the holy grail for every EV maker.

How does lightweighting improve EV range?

Less mass, less drag, less energy. That means longer range and smaller batteries, the ultimate win-win.

The Can Art Perspective: Partnering for Smarter EV Design

At Can Art Aluminum Extrusion, we believe innovation starts with collaboration. Our team partners with automotive engineers right from the design phase, making sure every extrusion is optimized for performance, manufacturability, and cost.

Here’s what we bring to the table:

- Expertise in 6000 series automotive alloys for strength and thermal control.

- Precision die design for complex, multi-hollow profiles.

- IATF 16949-certified processes for consistent automotive quality.

- Post-extrusion finishing, from machining and anodizing to full assembly optimization.

Whether it’s a battery enclosure, space frame, or crash management component, we help EV manufacturers turn smart design ideas into scalable, production-ready solutions.

Final Takeaway

Aluminum extrusions are quietly powering the EV revolution, making cars lighter, safer, more efficient, and more sustainable.

They’re not just structural components; they’re enablers of innovation, shaping how the next generation of vehicles will perform and endure.

At Can Art Aluminum Extrusion, we’re proud to be part of this transformation, helping our partners design the future of electric mobility, one profile at a time.