The global upswing in momentum for electric mobility is swift. As automakers make the switch from internal combustion to electric platforms, one engineering challenge stands above the rest: reducing vehicle weight without sacrificing safety or performance.

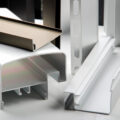

This is where aluminum extrusions have become a defining material solution. Combining strength, precision, and design flexibility, aluminum extrusions now play a critical role in developing battery enclosures, crash structures, and lightweight vehicle frames for the next generation of electric vehicles (EVs).

At Can Art Aluminum Extrusion Canada Inc., we work closely with automotive engineers to transform complex designs into high-performance, manufacturable aluminum components that meet the changing demands of electric mobility.

The Case for Lightweighting in Electric Vehicles

Every kilogram matters in an electric vehicle. The mass of a vehicle directly affects battery range, energy efficiency, and acceleration. That’s quite different from combustion engines, EVs can’t simply add more fuel to extend range; energy storage is limited by battery capacity and density.

According to the U.S. Department of Energy, a 10% reduction in vehicle weight can improve efficiency by around 6–8%. In the context of EVs, that can mean valuable extra kilometres of range from the same battery pack.

It’s not only about efficiency, lightweighting can also enable:

- Reduced structural loads allow for smaller motors and suspension components.

- Lower total cost of ownership, since less energy is needed for the same performance.

Steel alone cannot deliver the necessary weight reduction without adding complexity or compromising manufacturability. Aluminum, especially in extruded form, provides the ideal strength-to-weight ratio needed to achieve these performance gains.

Why Aluminum Extrusions Are Central to EV Design

Unlike castings or stampings, aluminum extrusions allow engineers to design hollow, multi-functional profiles that optimize structural integrity while minimizing material use. Through controlled extrusion, complex geometries can be achieved with tight dimensional tolerances and consistent mechanical performance.

The combination of precision and versatility makes aluminum extrusions ideal for a range of critical EV applications, from battery enclosures to crash structures to frame components.

- EV Battery Enclosures

Among the most challenging components within the architecture of an EV is its battery enclosure, or better said, pack housing. It must provide:

- Structural strength to support the weight of the battery modules.

- Crash protection, particularly during side or underbody impacts.

- Thermal management for stability in operational and charging temperatures.

- Corrosion resistance and electromagnetic shielding.

This is where aluminum extrusions come into their own. High thermal conductivity of the material assists in dissipating heat while its strength-to-weight ratio provides safety without excess mass.

Leading automakers, including Tesla, Ford, and GM, have adopted aluminum-intensive battery housings in their EV platforms, which in many cases incorporate extruded side rails and cross members into the enclosure frame.

- Structural Frames and Crash Management Systems

Extruded aluminum is used increasingly in side-impact beams, crumple zones, and roof structures, all of which rely on the material’s ability to absorb impact energy through controlled deformation.

According to the Aluminum Association, aluminum structures can absorb up to twice as much crash energy per unit weight as steel, making them ideal for protecting occupants and high-voltage systems in EVs.

At Can Art Aluminum Extrusion Canada Inc., we produce high-strength 6000-series extrusions, notably 6061 and 6082 alloys, optimized for both structural rigidity and energy absorption under crash loads.

- Lightweight Subframes and Chassis Components

EV makers are increasingly replacing conventional steel subframes and suspension components with extruded aluminum assemblies. These parts also contribute to lowering the centre of gravity of the vehicle, which improves handling and ride quality.

Aluminum extrusions are particularly well-suited for such applications because they can be welded, machined, and anodized without losing mechanical integrity, ensuring compatibility with diverse joining and finishing processes.

Advantages of Aluminum Extrusions in EV Manufacturing

1. Weight Reduction

Aluminum is approximately one-third the density of steel, offering major mass savings across structural and body components.

2. Corrosion Resistance

Natural oxide layers and anodized finishes protect against environmental degradation, extending component lifespan.

3. Recyclability

Aluminum can be recycled repeatedly with minimal loss of properties, supporting closed-loop manufacturing models.

4. Design Flexibility

Extrusions allow the integration of cooling channels, wiring, and mounting, reducing the need for several welded parts.

5. Performance Under Load

With optimized temper designations such as T6, 6000-series alloys provide the high yield strength and stiffness required for demanding automotive environments.

The Can Art Aluminum Extrusion Canada Inc. Approach to EV-Ready Aluminum Extrusions

As EV platforms evolve, so do the demands on materials and manufacturing. Can Art Aluminum Extrusion Canada Inc. provides a vertically integrated approach, from die design and alloy selection to extrusion, fabrication, and finishing, to ensure precision, repeatability, and structural integrity.

Our engineering teams work directly with OEMs and Tier 1 suppliers to:

- Optimize profile geometry for weight and strength.

- Select the appropriate alloy-temper combination based on functional performance and manufacturability.

The Road Ahead

It will take materials that enable efficiency without compromise to really shape the future of electric mobility. Light, strong, and infinitely recyclable, aluminum extrusions are positioned to remain the foundational elements in EV design for decades to come.

As OEMs continue to chase lighter and more efficient platforms, Can Art Aluminum Extrusion Canada Inc. continues to partner in the engineering of the structures that make electric mobility safer, more sustainable, and more advanced.